PRODUCT MESSAGE

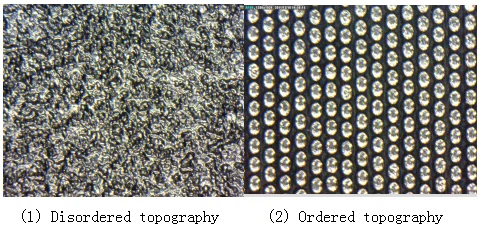

Disordered pits roll surface IPG 500W Fiber Laser Texturing Equipment

Overview

Questt QA-FLT500 laser texturing machine has equipped with imported fiber laser, the full system include fiber laser, control system and the domestic well-known brand of CNC .

It can realize roll roughen the processing laser chaos, make the roll surface disordered pits, meet the demand of a variety of surface topography.

Alternative to conventional shot peening roughen, edm roughen, other laser roughen orderly.Laser disordered roughen technology for the world first Independent research and development, and has a number of technology patents.

At present, the system have choices based on laser and roughen head number, we have single head and double head for your choices, according to the demand of customers.

Features

1. The system integration higher and higher control precision and stability is more reliable;

2. The equipment operation is simple, efficient;

3. The equipment operation cost is low;

4. High processing quality, energy saving;

5. Laser roughen processing good uniformity, high repeatability, morphology, no pollution, low energy consumption, low noise

6. Lifetime is more than 100,000 hours without failure.

7. Texturing process can be set according to the requirements set.

8. Roll surface roughness range of 0.5 ~ 15.0μm.

9. Alternative to conventional shot peening roughen, edm roughen, other laser orderly Roughen.

Specification

| Model | QA-FLT500 |

| Laser type | Imported Fiber laser |

| Output laser power | 500W |

| Laser frequency | 5-100KHZ |

| CNC system | Siemens or others |

| Roller diameter | 200-650mm |

| Working length | 0-5.3m |

| Texturing index | Ra=0.5-15um |

| The axial line density | 3-100 points/mm |

| The radial line density | adjustable |

| Small hole diameter | 50-90um |

| Small hole convex platform hardness | HV>800 |

| Small hole convex platform height | 2-25um |

Laser texturing head

The laser texturing device is composed of a large carriage, a small carriage, a focusing mirror and a detecting device. There are 2 sets of laser processing heads on the texturing head, 2 sets of manual focus adjustment devices, and each focus axis is equipped with a nitrogen side blowing device.

1 Large pallets Designed with a dedicated CNC roll texturing machine.

2 Small carriages Set on the large carriage, the transverse AC servomotors are driven laterally by two pairs of anti-backlash gears and transverse ball screws.

3 Focusing mirror and detecting device are all installed on the small carriage. The detection device is driven by the AC servo motor through the ball screw for linear motion.

4 Feed box: Designed with special CNC roll texturing machine.

Small pit surfaces of the laser Texturing steel sheets are not connected to each other, which is advantageous to oil and capture metal debris with stamping, prevent punching, to ensure the surface of the stamped parts, while reducing the amount of stamping oil. Deep punching performance is more excellent compared to processing techniques such as electric fire.

Application

Areas of application:

Steel, aluminum, titanium plate, etc.

Typical application:

Cold roller roughen processing, meet the temper mill, light machine, rolling mill, rolling mill roll after roughen the demand of various kinds of work roll.

Copyright © 2019 Wuhan QUESTT ASIA Technology Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.