Better Touch Better Business

Contact Sales at QUESTT.

CNC Smart Led Mirror Glass Laser Sandblasting Machine – a revolutionary advancement that transforms traditional sandblasting processes with cutting-edge laser technology.

Precision Laser Technology: Ensures accurate and consistent sandblasting results with minimal material wastage.

• Smart LED Mirror Glass: Provides clear visibility and precise targeting for intricate designs and patterns.

• Automated Operation: User-friendly interface with automated controls for ease of use and efficiency.

1. Enhanced Accuracy: Achieve intricate designs and patterns with unmatched precision.

2. Efficiency: Reduce material wastage and increase production speed compared to traditional sandblasting methods.

3. Safety: Eliminate harmful dust and reduce manual labor, creating a safer working environment.

4. Cost-effective: Lower operational costs with reduced maintenance and higher productivity.

Innovative Technology: Stay ahead of the competition with the latest laser sandblasting technology.

• Quality Assurance: Built to meet international quality standards, ensuring reliable performance and durability.

• Comprehensive Support: Our dedicated team provides training, technical support, and after-sales service to ensure your success.

Don't miss out on this opportunity to revolutionize your sandblasting operations. Invest in the future of glass etching technology with the CNC Smart Led Mirror Glass Laser Sandblasting Machine today!

Feel free to customize this introduction and promotion based on specific details and benefits of your product to better resonate with your target customers.

|

Num |

Item Name |

Model |

Qty |

Brand |

|

1 |

Gantry beam working table |

1300*2500mm |

1 set |

QUESTT |

|

2. |

Laser |

120W |

1 set |

JPT |

|

3. |

Water Chiller |

HL-1000 |

1 set |

Hanli |

|

5. |

Dust fan |

Special blower |

1 set |

QUESTT |

|

6. |

Laser marking head |

F160 |

1 set |

Galvo Scanner |

|

7 |

Control system |

1set |

Questt |

|

|

8 |

Device look color |

Blue and White |

|

Product Name |

CNC Smart Led Mirror Glass Laser Sandblasting Machine |

||

|

Laser Power |

80-120w |

Wavelength |

1064nm |

|

Marking Area |

1300×2500mm / 1500×3000mm / 2000×3000mm (customized) |

||

|

Plus Width |

2~20ns Adjustable |

Frenquency |

1~3000kHz |

|

Cooling Method |

Water-cooling |

Reducer |

Japan Shimpo |

|

Servo Motor |

Japan Yaskawa / Taiwan Syntec / Taiwan Delta (optional) |

||

|

Marking materials |

Glass,mirroring,all kinds of metal,opaque nonmetal materials etc. |

||

|

Processing speed |

35m/min |

||

|

XYZ traveling |

XYZ traveling positioning accuracy |

||

|

System Support |

Windows ALL(7-8-10-11) |

||

|

Format support |

Direct import of CAD files without generating code(dxf,dwg) |

||

|

Laptop/PC |

support |

||

|

Linear Guide |

Germany ASK |

Power Supply |

380V/220V |

|

Weight (KG) |

1200 KG |

Dimension(L*W*H) |

2500*1300*1100MM |

Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Restaurant, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

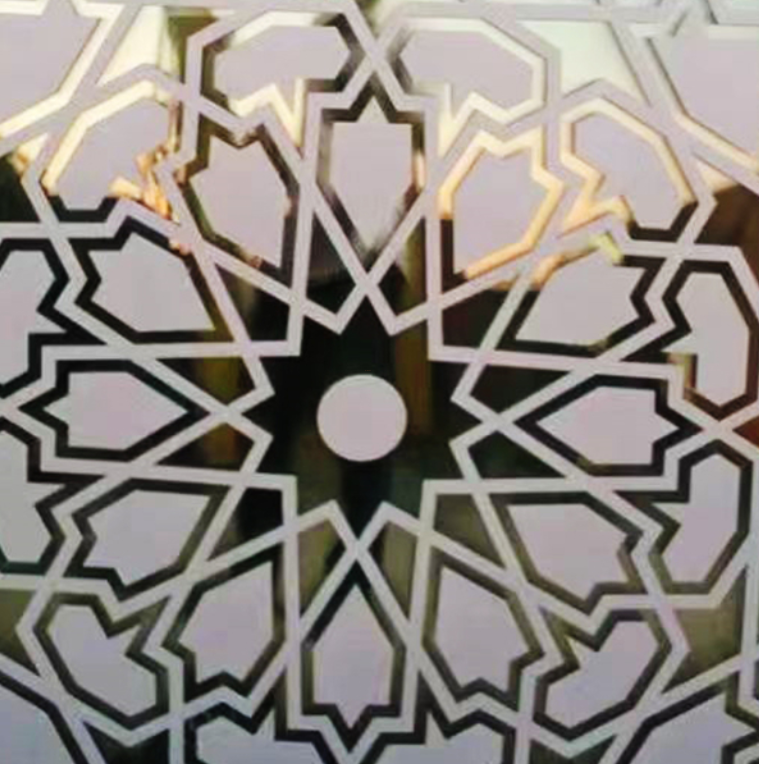

• Customized glass artworks

• Architectural glass designs

• Automotive glass etching

• Decorative mirrors and panels

Mirror sandblasting is a traditional method used to create frosted or textured patterns on glass surfaces. In this process, a stencil or mask is applied to the glass, leaving certain areas exposed. Then, fine abrasive particles, usually silicon carbide or aluminum oxide, are propelled at high speed onto the exposed areas using compressed air. This abrasive action etches the glass surface, creating the desired frosted effect.

Firstly, the abrasive particles can wear out the stencil quickly, leading to inconsistencies in the frosted patterns. Secondly, the process can be messy, producing a lot of dust and requiring extensive cleanup. Lastly, it can be time-consuming and labor-intensive, especially for intricate designs that require precise detailing.

In contrast, laser mirror sandblasting is a modern and innovative method that offers several advantages over traditional sandblasting. In this process, a laser beam is used to etch the glass surface directly, eliminating the need for abrasive particles and stencils.

The laser beam is precisely controlled to create intricate and uniform patterns with high accuracy. This allows for greater flexibility in design and ensures consistent quality across different pieces. Additionally, the laser process is clean and environmentally friendly, producing minimal dust and waste.

Moreover, laser mirror sandblasting is faster and more efficient than traditional methods, reducing production time and costs. It also offers better control over the depth and intensity of the etching, allowing for a wider range of creative possibilities.

While the CNC Smart Led Mirror Glass Laser Sandblasting Machine may have a higher initial investment, the long-term benefits in terms of efficiency, quality, and safety can result in significant cost savings and improved productivity. It offers a sustainable and innovative solution for modern glass etching needs, making it a worthwhile investment for businesses looking to stay ahead in the industry.

Copyright © 2019 Wuhan QUESTT ASIA Technology Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.