Better Touch Better Business

Contact Sales at QUESTT.

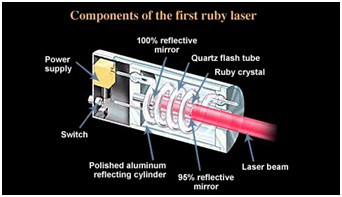

Originally, a light source was bounced back and forth through a Ruby crystal by two mirrors, amplifying a specific wavelength of light. One of the mirrors is not 100% reflective and therefore allows some of the light to escape through it in a narrow beam. We can then focus the beam further to a fine point produce sufficient heat to burn or melt materials that are placed in its path. Today, LASERs rarely use Ruby and the light beam can be created from many different sources.

There are five main types of LASER that are commonly used in industrial applications:

·Nd:+3YAG (Lamp Pumped)

·Nd:+3YAG or YVO4 (Diode Pumped)

·CO2 (Glass Tube)

·CO2 (Metal Tube)

·Fibre

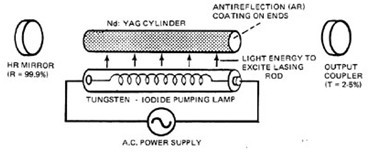

Nd:+3YAG and YVO4 are a man made and modern replacement for Ruby. In a Lamp Pumped Laser, a flash tube light is wrapped around the YAG rod to create the LASER source. In the Diode Pumped LASER, a Diode is placed either at the end of the rod (for better beam quality), or around the side (for higher power output). Hence, we can refer to these designs as Side-Pumped, or End-Pumped. A Lamp Pumped LASER can achieve a higher power output, whereas a Diode Pumped LASER offers a longer life span.

· #1 Requirements are for a 50W LASER. In this case, both DP and LP are capable of providing the required wattage.

· Thus, the Diode offers a longer lifespan making it the optimal choice.

· #2 Requirements are for a 300W LASER. In this case, the Diode is not capable of providing the required 300W. The

· Lamp Pump is therefore the only option.

Nd:+3YAG Diode Pumped and Lamp Pumped LASERs are extremely versatile. Ranging from 7W to 500W, they are capable of many tasks from marking and engraving to cutting and welding of a wide range of materials with high precision. Limitations include the material thickness (up to 6mm max), and the inability to work on textiles, paper, wood, etc. The beam is normally in the infrared range, however when fitted with a beam expander the light moves to the green spectrum and provides higher accuracy and beam quality.

CO2 LASERs are well suited to working with almost all materials (including paper and fabrics etc.) and in higher wattages, are also capable of cutting very hard metals. The only drawback is the lifespan of no less than 2000hrs. Benefits include the ability to cut through a wide range of very thick materials at high speed and precision.

Copyright © 2019 Wuhan QUESTT ASIA Technology Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.